Top Printable Circuit Board Designs You Need to Know?

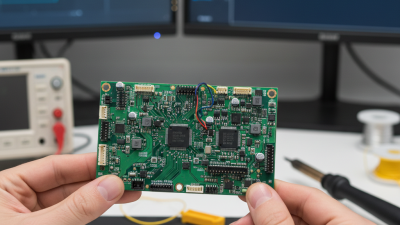

In the world of electronics, the popularity of printable circuit boards is on the rise. These innovative designs bring flexibility and creativity to engineers and hobbyists alike. Imagine crafting a circuit that fits perfectly into your unique project. The accessibility of printable circuit boards makes them an ideal choice for rapid prototyping.

However, not all designs are straightforward. Some require skill and careful planning. Beginners may find themselves struggling with complicated layouts or functionality issues. It’s essential to learn from mistakes in the design process. Each error can lead to a better understanding of how these circuits function. This exploration of printable circuit board designs will highlight key concepts and offer insights into successful implementations.

From simple concepts to complex configurations, each design tells a story of trial and error. This journey reveals the art of combining creativity and technical knowledge. Dive into the world of printable circuit boards and discover what designs you may want to explore.

Essential Features of Top Printable Circuit Board Designs

When exploring top printable circuit board designs, certain features stand out. Quality materials are crucial. A high-quality substrate ensures durability. Different thicknesses affect performance. A recent industry report highlighted that about 35% of failures in electronic devices can be traced back to poor PCB material selections. Designers must pay attention to these details during the creation phase.

Another essential feature is the layout design. A well-structured layout is vital for optimal signal integrity. Poorly arranged components can introduce noise and reduce efficiency. Studies indicate that a staggering 40% of design issues stem from inadequate layout planning. This emphasizes the need for meticulous attention to detail. Cluttered designs not only affect functionality but also complicate repairs. Re-evaluating designs often leads to significant improvements.

Lastly, functionality tests are indispensable. Regular testing during the prototyping phase can save time and costs. According to surveys, almost 50% of projects face delays due to overlooked testing phases. This is a painful reflection of how a lack of diligence can derail entire projects. Designers must embrace thorough testing to ensure reliability and safety.

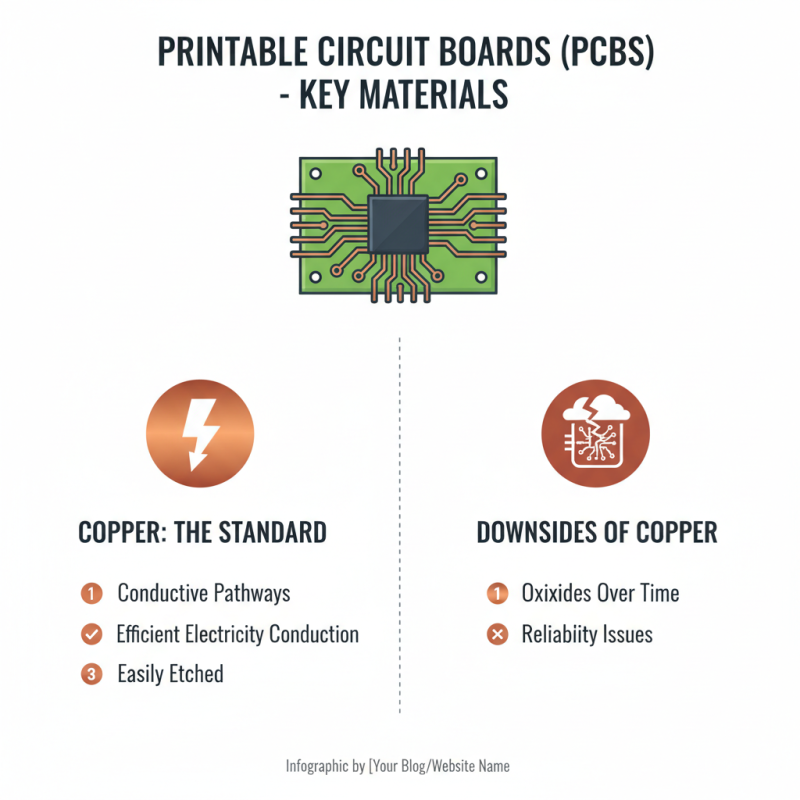

Key Materials Used in Printable Circuit Board Fabrication

Printable circuit boards (PCBs) rely on various key materials for their fabrication. Copper is the most common choice for conductive pathways. It efficiently conducts electricity and can be easily etched. However, using copper also has downsides. It can oxidize over time, leading to reliability issues in circuits.

Another important material is the substrate. It provides structural support to the PCB. Common substrates include FR-4, a fiberglass-based material, and polyimide for flexible PCBs. Each substrate offers unique properties. FR-4 is affordable and robust but can be brittle. Meanwhile, polyimide allows for bending but can be costly.

Insulating materials are also crucial. They prevent unwanted electrical connections. Typical options include epoxy and silicone. These materials must be chosen carefully. The insulation needs to withstand heat and environmental factors. In some cases, manufacturers fail to prioritize the right choices. This can lead to weak circuits and reduced lifespan. Understanding these materials is vital for successful PCB design.

Popular Printable Circuit Board Design Techniques and Methods

Printable circuit board (PCB) design has evolved significantly. Many enthusiasts and professionals now prefer various techniques. Among these methods, two stand out: software-aided design and hand-drawn layouts. According to a report by Research and Markets, the global PCB market is expected to reach $82.2 billion by 2027. This growth emphasizes the rising demand for innovative designs.

Software tools offer precision and efficiency. These programs allow designers to create complex layouts quickly. However, reliance on technology can lead to oversight. Errors may go unnoticed. Manual techniques, although time-consuming, promote a deeper understanding of circuit functions. Some designers find this balance crucial. They mix both methods for optimal results.

Traditional methods like photo-masking and etching still hold value. They provide tactile feedback in the design process. However, they're often seen as outdated. This perception can discourage new designers. Embracing both old and new techniques can enrich knowledge. Ignoring historical approaches may limit creativity. As the industry grows, so should the techniques used. Balancing precision and tradition is key in crafting effective designs.

Top Printable Circuit Board Designs

Applications of Printable Circuit Boards in Modern Technology

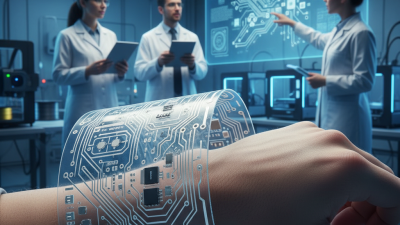

Printable circuit boards (PCBs) have become crucial in modern technology. They are lightweight, flexible, and customizable. These features enable various applications across industries. From consumer electronics to automotive systems, their impact is significant.

In consumer electronics, PCBs are the backbone of devices. Smartphones, tablets, and wearables rely heavily on these designs. They allow complex functions within a compact space. Yet, the sustainability of manufacturing processes remains a concern. Many PCBs contain materials that may not be easily recyclable.

In medical technology, PCBs play a vital role as well. They are found in diagnostic tools and monitoring devices. Precision in design can be life-saving. However, the reliance on advanced technology poses challenges. Regular updates in design may lead to obsolete parts, complicating repairs and replacements. With rapid advancements, engineers face the task of balancing innovation and durability.

Best Practices for Designing and Printing Circuit Boards

When designing and printing circuit boards, attention to detail matters. Make sure your layout is clear and organized. This can help reduce mistakes during the manufacturing process. According to a recent study by the Electronic Design Automation (EDA) Consortium, nearly 30% of reworks in circuit board manufacturing are due to design errors. Therefore, proper planning is crucial.

Tips: Use software tools that provide real-time feedback. These tools can catch errors before printing. Also, consider the thickness of the components. A mismatch can lead to performance issues. Keeping traces at optimal widths can enhance electrical conductivity while minimizing heat.

It's important to reflect on your designs. Ask yourself questions. Is the layout intuitive? Are components spaced appropriately? The average failure rate in prototype boards is about 20%. Identifying design flaws early saves time and cost in the long run. Don't overlook the importance of thorough testing before final production. Each step in the process can significantly impact the final product and its effectiveness.

Top Printable Circuit Board Designs You Need to Know

| Design Type | Layer Count | Material | Common Uses | Printing Technique |

|---|---|---|---|---|

| Single Layer PCB | 1 | FR-4 | Basic electronics, consumer gadgets | Silkscreen and Solder Mask |

| Double Layer PCB | 2 | FR-4 | LED lighting, industrial equipment | Etching and Printing |

| Multilayer PCB | 3+ | Epoxy Glass | Telecommunications, high-speed circuits | Laser Direct Imaging |

| Flexible PCB | 1+ | Polyimide | Wearable technology, automotive applications | Screen Printing |

| Rigid-Flex PCB | 1+ | FR-4 & Polyimide | Consumer electronics, aerospace | Layer Stacking |

Related Posts

-

What is PCB Prototyping and Why is it Important?

-

Top 10 PC Boards for Optimal Performance in 2023

-

How Printed Circuit Boards Shape the Future of Technology with Insights from Industry Trends

-

10 Essential Tips for Designing High-Quality PCB Flex Circuits

-

Why Printable Circuit Boards are Revolutionizing Modern Electronics Design

-

What is PCB Fabrication and How Does it Impact Your Electronics Projects