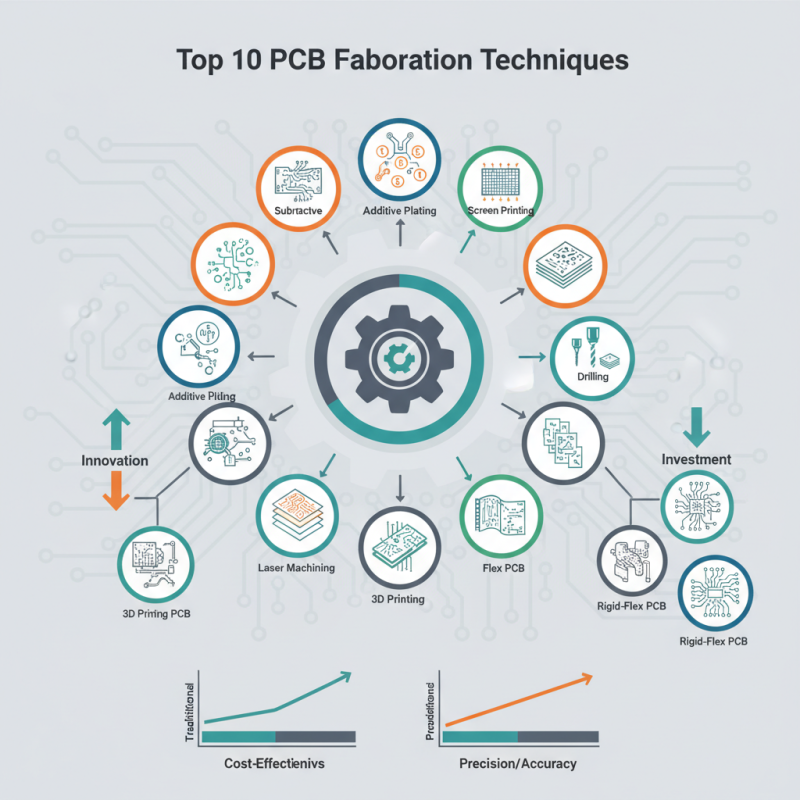

Top 10 PCB Fabrication Techniques You Should Know?

In the rapidly evolving world of electronics, understanding PCB fabrication is crucial. Manufacturers rely on various techniques to create reliable printed circuit boards. These boards play a vital role in modern devices, from smartphones to complex machinery.

Each fabrication technique presents unique benefits and challenges. For instance, traditional methods may be cost-effective but may not meet high precision demands. Emerging technologies focus on improving accuracy and reducing waste. However, they often require significant investment in new machinery and training.

Innovations continue to reshape the PCB landscape. Whatever technique you choose, knowledge of these methods will empower you. This understanding allows you to make informed decisions and improve your projects. Embracing these practices is key to staying competitive and meeting ever-increasing consumer expectations.

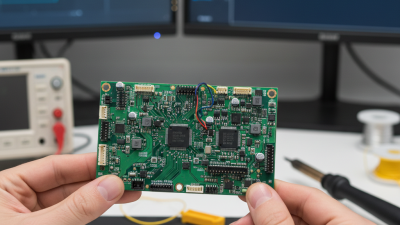

Understanding PCB Fabrication: An Overview of the Process

Understanding PCB fabrication is crucial for anyone in electronics. The process begins with design. Engineers create layouts using specialized software. This design is then transferred onto a copper-clad board. The board undergoes various techniques to create the desired circuitry.

Once the layout is on the board, etching follows. Chemicals remove unwanted copper, forming the necessary paths. However, this step can be tricky. If not executed well, it can lead to unintended connections or broken circuits. Another vital process is drilling. This creates holes for components. Precision is key here, as errors can disrupt the whole functionality.

After drilling, a solder mask is applied. This layer protects the copper and prevents solder bridging. Yet, achieving uniformity can be challenging. Poor application may lead to areas susceptible to damage. Finally, the finishing touches include applying silkscreen for labels. Each stage in PCB fabrication presents unique challenges. Addressing these challenges is essential for creating reliable, high-quality products.

The Role of Design Software in PCB Fabrication Techniques

The design software plays a crucial role in PCB fabrication techniques. It allows engineers to create intricate designs and layouts with precision. A good software package provides tools for simulation and testing, ensuring that designs meet specifications before production. This saves time and reduces costly mistakes during fabrication.

However, not all software solutions are perfect. Some may have a steep learning curve. Engineers often find themselves struggling to master the features. Sometimes, the interface may feel cluttered and overwhelming. Learning shortcuts can be beneficial, but it takes time to figure them out. Limited support for certain features can also hinder productivity.

Moreover, collaboration can be a challenge. Different team members may use various software tools, causing compatibility issues. This can lead to miscommunication and errors in the design. Engineers should be mindful of these potential setbacks. Always ensure that everyone is on the same page. Regular training and updates can help improve the design process. Balancing software capabilities with real-world constraints is key to effective PCB fabrication.

Common Substrate Materials Used in PCB Manufacturing

In PCB manufacturing, substrate materials play a crucial role. Among the common types, FR-4 remains the most widely used. It consists of woven glass epoxy and offers good electrical insulation. Its unique properties make it ideal for various electronic applications. Data from a recent market analysis shows that FR-4 holds over 70% of the global PCB substrate market.

Another notable substrate is polyimide. This material is known for its high heat resistance and flexibility. While more expensive than FR-4, polyimide is often required in high-performance environments. According to industry reports, its demand is increasing, especially in aerospace and automotive sectors. This shift highlights a growing trend in requiring advanced materials for reliable performance.

Tips: When selecting a substrate, consider factors like thermal management and electrical performance. Sometimes, cheaper options might compromise quality. Always weigh short-term savings against long-term reliability. Collecting feedback from engineers can also guide better choices in material selection.

Top 10 PCB Fabrication Techniques - Common Substrate Materials Used

Step-by-Step Overview of PCB Etching Processes

PCB etching is a crucial process in the fabrication of printed circuit boards. This step removes unwanted copper from the board, leaving the desired circuit pattern. The process typically starts with a copper-coated substrate. A photoresist layer is applied to protect specific areas of the copper.

Once the photoresist is set, it’s exposed to ultraviolet light through a mask. This step is vital; any mistakes here can lead to errors in the final circuit. After exposure, the board undergoes a development process to wash away unexposed photoresist. This reveals the copper underneath, ready for etching.

The etching solution, often composed of chemicals like ferric chloride, removes the exposed copper. Careful control of the etching time is crucial. Too short, and the etching might be incomplete; too long, and you risk damaging the board. After etching, the remaining photoresist is stripped away, revealing the final circuit pattern. Throughout the process, quality checks are essential to ensure accuracy and prevent costly mistakes.

Innovations in Soldering Techniques for Enhanced Circuit Performance

Soldering techniques are evolving rapidly. Innovations are changing how circuits perform and last. Some methods focus on improving thermal management. This is essential for high-performance applications.

Reflow soldering is gaining popularity. It produces consistent results with minimal defects. However, achieving the perfect temperature profile can be tricky. Most engineers find it challenging to avoid cold solder joints. Another method, wave soldering, offers reliability but comes with its own set of complexities. Controlling the wave height and speed requires practice.

Selective soldering is another advancing technique. It offers precision for complex boards. Still, mastering this technique demands skill and patience. Mistakes can lead to inadequate solder joints. Each method has its strengths and weaknesses. Continuous improvement is crucial for future advancements. This requires a willingness to refine techniques and learn from errors.

Related Posts

-

What is PCB Fabrication and How Does it Impact Your Electronics Projects

-

What is PCB Prototyping and Why is it Important?

-

Why Understanding PCB Production is Essential for Modern Electronics

-

Top 10 PCB Fast Manufacturing Techniques to Improve Efficiency?

-

Top Factors Influencing PCB Production Quality and Cost?

-

How to Start PCB Prototyping for Your Electronics Projects?