Understanding the Essential Role of Printed PCBs in Modern Electronics

In the rapidly evolving landscape of modern electronics, the significance of printed PCBs (printed circuit boards) has never been more pronounced. As industry reports indicate, the global PCB market is projected to reach approximately $83 billion by 2026, driven by the burgeoning demand for electronic devices across various sectors including telecommunications, automotive, and consumer electronics. According to a study by Research and Markets, the printed PCB segment accounts for a substantial share of this growth, attributed to advancements in technology and manufacturing processes that enhance their performance and integration capabilities. With the proliferation of IoT devices and the shift towards smart technologies, the role of printed PCBs in ensuring reliability and efficiency in electronic systems cannot be overstated, positioning them as a cornerstone in the foundation of innovation and progress in this digital age.

The Fundamental Functions of Printed Circuit Boards in Electronics

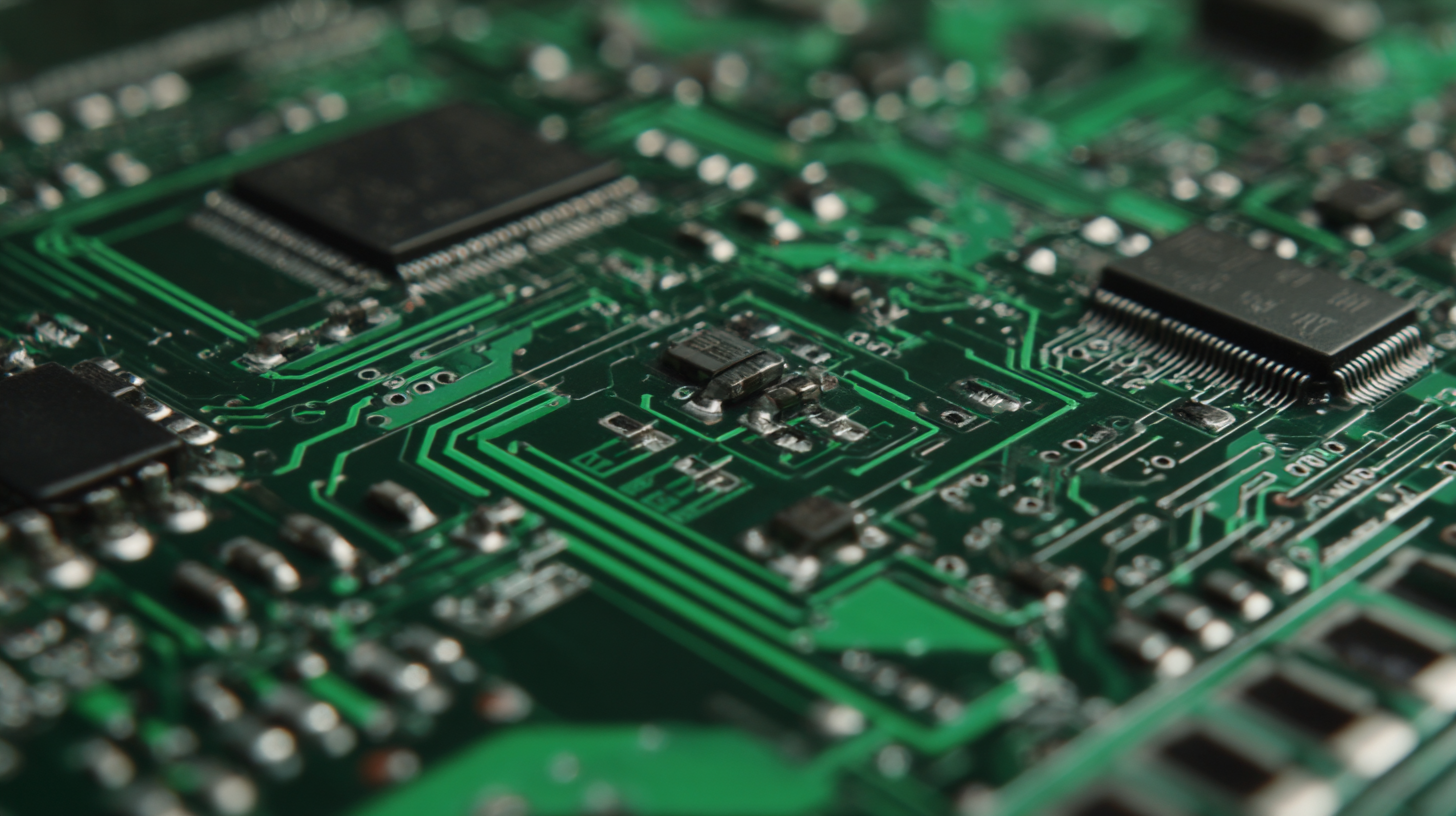

Printed circuit boards (PCBs) play a fundamental role in modern electronics, serving as the backbone of nearly all electronic devices. They provide a structured platform for connecting various electronic components, such as resistors, capacitors, and microchips. By using conductive pathways etched from copper sheets, PCBs enable efficient electrical connections and signal transmission, reducing the risk of short circuits and ensuring reliable functionality. The layout of the PCB is meticulously designed to optimize space and maintain performance, accommodating the specific requirements of each electronic application.

Additionally, PCBs are essential for the functionality and durability of electronic devices. They facilitate the integration of complex circuits within a compact design, making it possible for devices to become smaller and more powerful. The use of PCBs also aids in thermal management, as they can dissipate heat effectively during operation. This is crucial for maintaining the longevity and reliability of electronic products, especially in high-performance environments. Overall, the significance of printed circuit boards cannot be overstated, as they are integral to the advancement and innovation within the electronics industry.

Exploring the Manufacturing Process of Printed PCBs

The manufacturing process of printed circuit boards (PCBs) plays a crucial role in the electronics industry, with industry reports projecting the global PCB market to reach $75.6 billion by 2026. This growth is largely driven by the rising demand for sophisticated electronic devices in sectors such as automotive, telecommunications, and consumer electronics. The production of PCBs involves several key steps, including design, etching, and assembly, each requiring precise engineering and technology to ensure reliability and performance.

During the design phase, engineers utilize advanced software tools to create schematics and layouts that dictate how electronic components will be arranged on the board. Following this, the etching process employs chemicals and lasers to remove unnecessary copper from the board, forming the necessary patterns. Assembly entails placing components onto the PCB, which can be accomplished through manual or automated techniques. According to a report by IPC, the adoption of automated assembly processes has increased by 30% in the past five years, reflecting a shift towards higher efficiency and consistency.

**Tips:** When designing PCBs, always consider the thermal management aspects, as overheating can significantly impact performance. Additionally, employing a good PCB design software can streamline the process, helping to minimize errors and save time. Keep an eye on the latest advancements in PCB materials and technologies, as they can enhance both the durability and functionality of your products.

Understanding the Essential Role of Printed PCBs in Modern Electronics

This chart illustrates the distribution of various materials used in the manufacturing process of printed circuit boards (PCBs), highlighting their essential roles in modern electronics.

Key Advantages of Using Printed PCBs in Modern Devices

Printed Circuit Boards (PCBs) serve as the backbone of modern electronics, providing a reliable foundation for complex circuits. One of the key advantages of using printed PCBs is their space efficiency. The compact design of PCBs allows more components to be integrated into smaller devices, facilitating the miniaturization that is essential for consumer electronics. This optimization not only enhances portability but also improves performance by minimizing the distance electrical signals must travel between components.

Another significant benefit of printed PCBs is their cost-effectiveness in mass production. Once a design is finalized, PCBs can be manufactured at scale with high precision and consistency, reducing the overall production costs. This scalability makes them attractive not only for large electronics manufacturers but also for small startups looking to bring innovative products to market quickly. Furthermore, the reliability of printed PCBs contributes to longer product lifespans, as they are less prone to failure compared to traditional wiring methods, ensuring devices operate smoothly over time.

Common Applications of Printed Circuit Boards in Various Industries

Printed Circuit Boards (PCBs) play a vital role in a wide array of modern electronic applications, acting as the backbone of electronic circuits. In consumer electronics, single-sided and double-sided PCBs are commonly employed to streamline the manufacturing process and reduce production costs. These boards enable the efficient integration of various components, which is essential for devices like smartphones, laptops, and home appliances. Additionally, the rise of IoT technology has further increased the demand for sophisticated PCB designs that support smart features and connectivity.

In the automotive and industrial sectors, multilayer and rigid-flex PCBs facilitate the complex circuitry of advanced systems and safety features. With the growing popularity of electric vehicles and automation, the need for reliable and durable PCBs has never been greater. Moreover, the medical sector has seen an uptick in the use of flex PCBs due to their lightweight and flexible characteristics, allowing for compact device designs that are critical in medical monitoring and diagnostic tools. These diverse applications highlight the significance of printed PCBs in driving innovation across various industries in today's technology-driven world.

Understanding the Essential Role of Printed PCBs in Modern Electronics - Common Applications of Printed Circuit Boards in Various Industries

| Industry | Common Application | PCB Type | Key Features |

|---|---|---|---|

| Consumer Electronics | Smartphones | Multi-layer PCB | Compact design, high-frequency performance |

| Automotive | Navigation Systems | Rigid PCB | High durability, thermal stability |

| Healthcare | Medical Devices | Flexible PCB | Lightweight, adaptable to various shapes |

| Telecommunications | Routers | High-density interconnect PCB | High data rates, compact layout |

| Aerospace | Flight Control Systems | Rigid-flex PCB | Reliability, flexibility in space-constrained designs |

| Industrial Automation | Control Panels | Single-sided PCB | Cost-effective, easy to manufacture |

Future Trends in PCB Technology and Their Impact on Electronics

The rapid growth of the automotive PCB market is a clear indicator of how printed circuit boards are evolving to meet the demands of modern electronics. Expected to rise from $9.15 billion in 2023 to $15.1 billion by 2032, this market will experience a compound annual growth rate (CAGR) of 5.9%. As vehicles become increasingly embedded with electronic systems to enhance safety, comfort, and efficiency, the role of PCBs becomes even more critical.

In recent years, several trends have emerged within PCB technology. One notable trend is the shift towards high-density interconnect (HDI) and flexible circuits, which allow for more compact designs and functionality. These advancements not only improve the performance of electronic devices but also open doors for new applications in the automotive sector. As the industry moves toward autonomous and electric vehicles, the demand for more sophisticated and reliable PCBs will continue to grow.

Tips: When considering PCB technology for your projects, it's essential to assess the specific requirements of your application. Standard multilayer boards might suffice for basic functions, while HDI boards may be necessary for complex, high-performance systems. Additionally, staying updated on material innovations will ensure your designs are at the forefront of technology.