What is PCB Prototyping and Why is it Important?

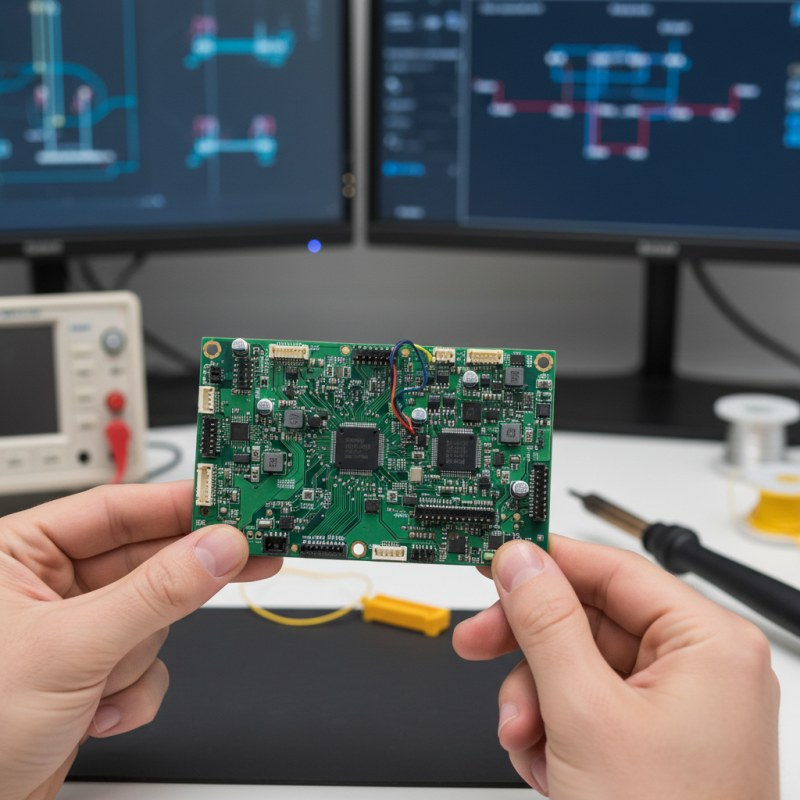

PCB prototyping is a crucial step in the development of electronic devices. It allows engineers to test and validate their designs quickly. By creating a physical model, they can identify issues early in the process. This prevents costly mistakes later on.

In today's fast-paced tech world, having a reliable PCB prototype is vital. It bridges the gap between concepts and real-world applications. However, many still overlook its importance. Rushing through the prototyping phase can lead to flawed products. Consider the potential consequences of a failed prototype.

Mistakes during PCB prototyping can impact the entire project timeline. Engineers should invest time into this stage. Quality and precision in prototypes can lead to successful product launches. Embracing a thorough approach can save resources in the long run.

Understanding PCB Prototyping: Definition and Overview

PCB prototyping is a critical process in electronics design. It involves creating a scaled-down version of a printed circuit board (PCB). This prototype helps engineers test the design before full-scale production. Prototyping allows for early detection of design flaws, which can save both time and resources.

One tip for effective prototyping is to focus on key components. Identify which parts of your design are most likely to benefit from testing. This can streamline the process and highlight areas that need improvement. Remember, not every detail must be perfect at this stage.

Another useful tip is to gather feedback early. Share your prototype with peers or potential users. Their insights can reveal overlooked issues. Engaging others in the testing phase fosters collaboration and enhances the design. Be open to criticism; it’s a step toward refinement. The prototyping process is iterative, making adjustments based on feedback essential for success.

Key Steps in the PCB Prototyping Process

The PCB prototyping process is crucial in electronics design. It involves several key steps that ensure functionality and reliability. The first step is schematic design, where engineers create a digital representation of the circuit. According to industry reports, this phase can take around 10% of the overall project time.

Next, PCB layout comes into play. This step involves placing components accurately on the board. Reports indicate that a well-planned layout can reduce production costs by up to 20%. However, many engineers overlook the importance of spacing and routing, leading to wasted effort later in the process.

After layout, the fabrication phase begins. Here, a manufacturer creates the physical board based on the designs. Research shows that approximately 30% of prototypes face issues during fabrication due to design oversights. Engineers must carefully review each step to avoid this pitfall. Ultimately, successful prototyping requires attention to detail and proactive problem-solving to navigate challenges efficiently.

Benefits of PCB Prototyping in Product Development

PCB prototyping is a crucial step in product development. It allows engineers to test and validate their designs before moving to mass production. Recent industry reports indicate that approximately 70% of engineering teams utilize PCB prototypes to identify design flaws early. Early detection can save companies up to 30% in potential costs associated with design revisions.

The benefits of PCB prototyping extend beyond cost savings. Rapid prototyping, for instance, enables quick iteration cycles. Teams can test multiple versions of a circuit board in a short timeframe. This agility fosters innovation, but it can also lead to oversight. Sometimes, the rush to prototype can overlook critical details, leading to performance issues later. Ensuring quality without sacrificing speed is a balancing act that challenges many teams.

Moreover, prototyping also improves communication among stakeholders. Visualizing the product helps bridge the gap between technical and non-technical team members. Yet, not all teams utilize prototyping to its full potential. In fact, studies show that around 40% of teams still rely on outdated methodologies. This reluctance can hinder progress and may prevent the realization of optimal product designs. Embracing prototyping fully could transform the development landscape significantly.

Benefits of PCB Prototyping in Product Development

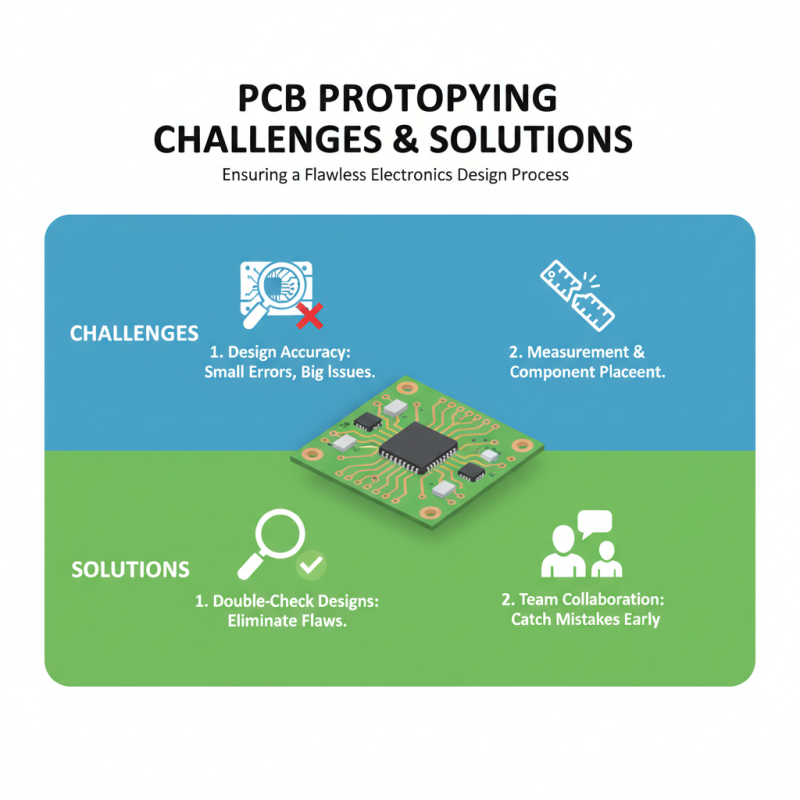

Common Challenges in PCB Prototyping and Solutions

PCB prototyping is an essential step in electronics design. However, many face common challenges during this process. One challenge is ensuring design accuracy. Often, small errors can lead to major issues later. Inaccurate measurements or misplaced components can be costly. Double-checking designs helps eliminate these flaws. Collaborating with team members may also catch potential mistakes.

Another challenge involves material selection. Choosing the right substrate affects both functionality and cost. Some materials may not be easily available or suitable for specific applications. Conducting thorough research on material properties is vital. However, it’s not always straightforward. Sometimes the best choice emerges only through trial and error. This iterative process can be frustrating but is crucial for success.

Lastly, time constraints can hinder prototyping efforts. Rushing may lead to rushed decisions and subpar results. Tight deadlines often force compromises on quality or thorough testing. Taking time to refine a prototype may slow progress, but it can save time and resources in the long run. Balancing speed with quality remains a common struggle for many in the field.

The Future of PCB Prototyping: Trends and Innovations

The future of PCB prototyping is bright, with new trends and innovations shaping the landscape. As technology advances, the demand for faster prototyping increases. According to a recent market report, the PCB prototyping market is expected to grow at a CAGR of 8.5% from 2023 to 2028. This growth highlights the need for more efficient processes.

One exciting trend is the rise of additive manufacturing. This technology allows for faster iterations and reduced material waste. Companies are looking to shorten development cycles. However, challenges remain. Not all designs are suitable for additive processes, and traditional methods still hold value.

Tip: Consider using 3D printing for quicker prototypes. It can significantly reduce lead time. Another notable innovation is the integration of AI in PCB design. AI can optimize layouts and predict failures before they occur. Yet, relying too heavily on automation can lead to oversight. Engineers need to maintain a balance between technology and human expertise.

What is PCB Prototyping and Why is it Important?

| Aspect | Description | Importance | Trends & Innovations |

|---|---|---|---|

| Definition | The process of creating printed circuit boards (PCBs) for testing and refining product designs. | Helps in identifying design issues early in the development cycle. | Increase in AI integration for automated PCB design. |

| Speed | Rapid prototyping allows faster turnaround for testing new ideas. | Accelerates the product development process. | Adoption of 3D printing technologies for quick prototypes. |

| Cost-Effectiveness | Allows solving design problems without high production costs. | Reduces financial risk in product development. | Increased availability of affordable prototyping services. |

| Customization | Prototypes can be tailored to specific requirements. | Enhances user satisfaction and product performance. | Emergence of customizable PCB design software tools. |

| Testing | Facilitates real-world testing of PCB designs. | Ensures reliability and functionality of the final product. | Increased use of simulation software for early-stage testing. |

Related Posts

-

What is PCB Fabrication and How Does it Impact Your Electronics Projects

-

Why Understanding PCB Production is Essential for Modern Electronics

-

Top 10 PC Boards for Optimal Performance in 2023

-

How to Start PCB Prototyping for Your Electronics Projects?

-

Top 10 PCB Fast Manufacturing Techniques to Improve Efficiency?

-

Why Printable Circuit Boards are Revolutionizing Modern Electronics Design