2026 How to Optimize Production PCB for Efficient Manufacturing?

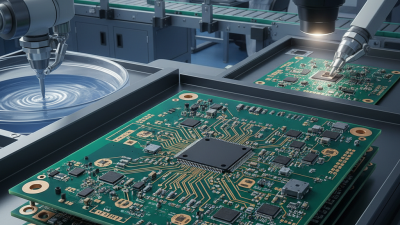

In the fast-paced world of electronics, optimizing production PCB is crucial. Efficient manufacturing processes lead to reduced costs and increased productivity. Designers and manufacturers must collaborate to achieve this goal.

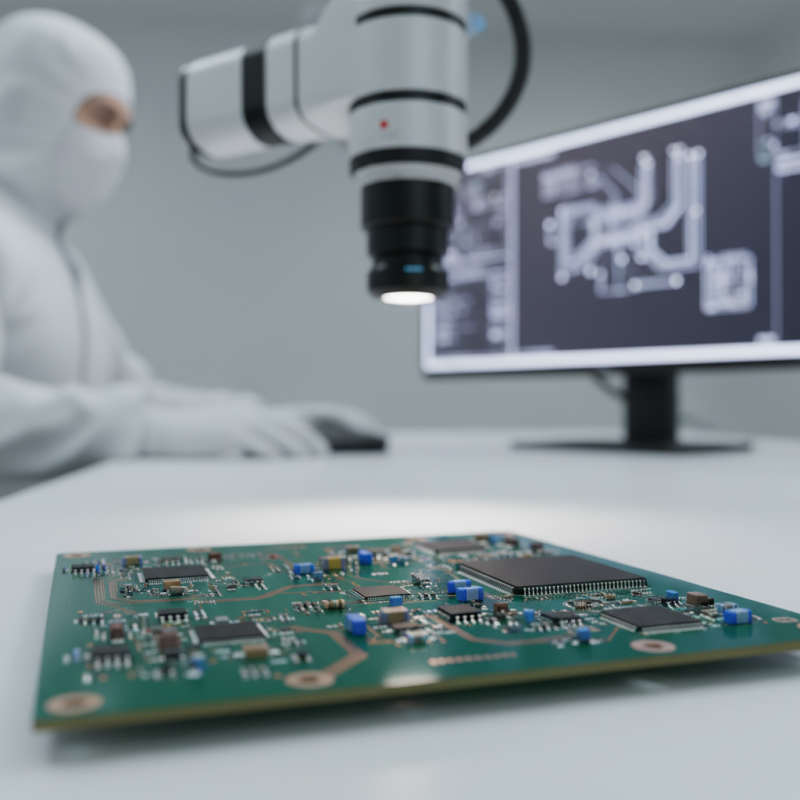

The design of production PCB should prioritize simplicity and functionality. Complex layouts can complicate manufacturing. It’s essential to consider the component placement strategically. Inadequate spacing may lead to assembly errors, delaying production timelines.

However, not all approaches yield perfect results. Sometimes, over-optimization can lead to unforeseen issues. For instance, while minimizing layers might cut costs, it could compromise performance. Manufacturers need to strike a balance between cost and efficiency. Reflecting on past projects can help improve future PCB designs and manufacturing strategies.

Understanding PCB Design Principles for Manufacturing Efficiency

When optimizing PCB design for manufacturing efficiency, understanding core design principles is crucial. Research indicates that poor PCB layout leads to manufacturing delays. In fact, a survey by IPC showed that around 30% of PCB production issues stem from design flaws. Simplifying the design can significantly reduce these problems.

Effective routing is essential. Keeping trace lengths short helps minimize resistance and improves signal integrity. Designers should also consider the placement of components carefully. Clustering similar components can facilitate easier assembly. In contrast, poorly organized layouts can lead to costly reworks. A detailed analysis from a reputable source showed that a well-organized board design can reduce assembly time by 25%.

Thermal management is another key aspect. Heat-generating components must be spaced out effectively. Overheating can lead to malfunctions and increased production costs. A noted 40% of failures in electronics result from thermal issues. Designers need to incorporate ample heat dissipation strategies early in the design phase, leading to a more robust final product. Emphasizing these principles can aid in creating PCBs that meet both efficiency and quality demands.

Production PCB Design Principles for Manufacturing Efficiency

Selecting Suitable Materials for Optimized PCB Production

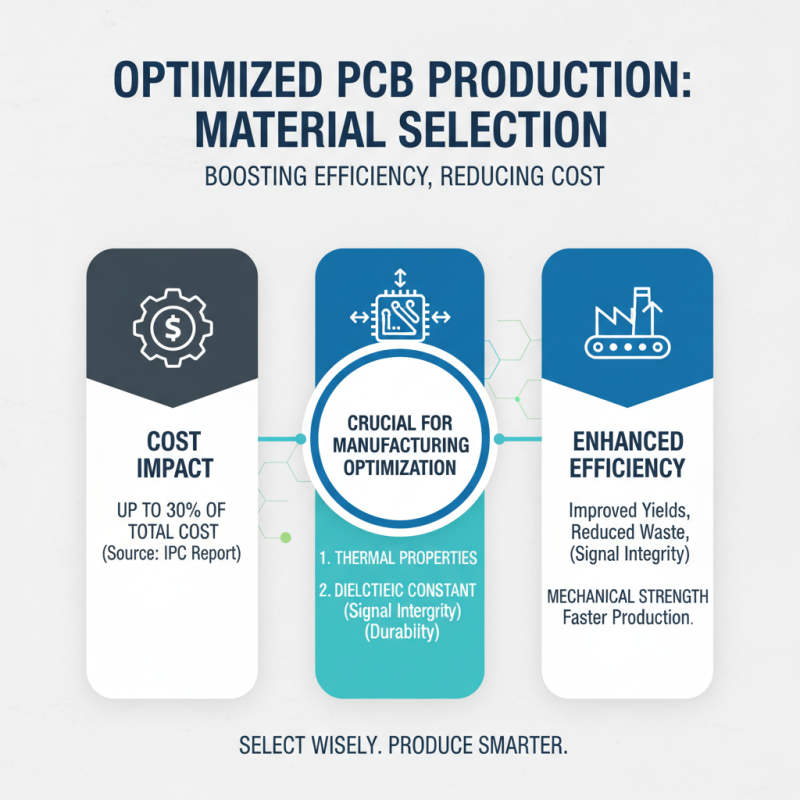

Selecting suitable materials for optimized PCB production is crucial for enhancing manufacturing efficiency. According to a report from IPC, material selection can influence up to 30% of the total cost in PCB production. This statistic underscores the importance of evaluating several factors, including thermal properties, dielectric constants, and mechanical strengths when choosing materials.

A common choice for PCBs is FR-4, known for its excellent balance of cost and performance. However, specialized applications might require advanced materials like polyimide or Rogers substrates. These options can improve thermal performance but often at a higher expense. The decision should be guided by the specifics of each project. A PCB designed for high-frequency applications needs materials that maintain signal integrity under varying temperatures.

Reflecting on the material choices, it’s essential to consider trade-offs. More expensive materials might not always yield significant benefits. For low-volume productions, investing heavily in premium materials may lead to increased costs without proportional gains in quality. Analyzing real-world data and testing prototypes can help optimize this balance. Always remember, the best choice isn’t merely about performance; it’s about achieving the best value for your production goals.

Implementing Advanced Design Techniques to Reduce Production Costs

Optimizing production PCB is essential for cost-effective manufacturing. Advanced design techniques can significantly reduce costs. One effective method involves simplifying the layout. A clean layout minimizes trace lengths, leading to decreased production complexity. This step can enhance both reliability and manufacturability.

Another strategy is to use fewer layers in the PCB. Double-sided boards are often easier and cheaper to manufacture than multi-layer options. However, this approach may require compromises on functionality. Designers must strike a balance between complexity and cost. Keeping components organized helps when reducing layers.

Designers should also consider component placement carefully. Clustering components can help streamline assembly processes. This decreases labor time and potential errors during manufacturing. Yet, improper placement might lead to heat dissipation issues. Each decision can impact overall performance. Reflecting on these factors is crucial for optimal results.

Utilizing Automation and Technology in PCB Manufacturing Processes

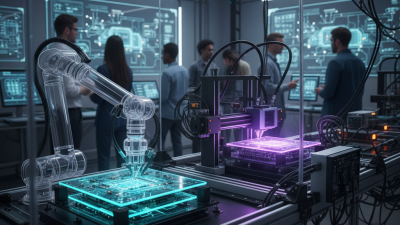

In the world of PCB manufacturing, automation plays a critical role. Machines now handle many tasks once done by hand. This shift reduces errors and speeds up the process. For instance, automated soldering machines apply solder precisely. They minimize waste and enhance quality. However, it’s essential to regularly calibrate these machines. Over time, even the best systems may drift from optimal performance.

Technology also aids in design optimization. Advanced software can simulate PCB performance before physical production starts. It allows engineers to identify issues early. Yet, these tools require training and can be complex. Staff must adapt to new systems. This can be a challenge, leading to mistakes if not properly managed. Consider investing in continuous training programs for the team.

Despite the benefits, not every operation suits full automation. Certain tasks need human oversight. For example, quality inspection still relies heavily on skilled personnel. Machines may miss subtle defects. Human eyes catch what machines sometimes overlook. Therefore, finding the right balance between automation and human touch is crucial in PCB manufacturing.

2026 How to Optimize Production PCB for Efficient Manufacturing? - Utilizing Automation and Technology in PCB Manufacturing Processes

| Dimension | Description | Impact on Efficiency | Technology Used |

|---|---|---|---|

| Design Automation | Utilizing CAD tools to streamline PCB layout and design. | Reduces design cycle time by up to 30%. | Eagle, Altium |

| Manufacturing Automation | Automated pick-and-place machines for component assembly. | Increases production speed by 50%. | SMT machines, Robotics |

| Testing Automation | Implementing automated testing systems for quality assurance. | Improves defect detection rate by 40%. | Flying Probe Testers, Functional Test Systems |

| Supply Chain Integration | Connecting suppliers, manufacturers, and logistics for real-time data sharing. | Reduces lead time by 20%. | ERP Systems, IoT |

| Data Analytics | Leveraging data analytics for decision-making and process improvement. | Enhances operational efficiency by 25% through better insights. | Business Intelligence Tools |

Evaluating Supply Chain Strategies for Streamlined PCB Production

Effective supply chain strategies are crucial for optimizing PCB production. Streamlined processes help reduce waste and improve efficiency. When evaluating suppliers, it is essential to consider their reliability. A dependable supplier can ensure timely material delivery, impacting the overall production schedule. Analyzing lead times is vital. Long lead times can disrupt your workflow and create bottlenecks.

Collaboration among all stakeholders enhances PCB production efficiency. Regular communication with suppliers can clarify expectations and resolve issues quickly. It is beneficial to create a feedback loop for continuous improvement. It's worth reflecting on past experiences with supply chains. Were there moments of delay? How could better communication have changed the outcome?

Investing in technology can also enhance supply chain evaluations. Data analytics can offer insights into supplier performance. Tracking metrics like on-time delivery rates can guide future decisions. Embrace flexibility within your supply chain. Unexpected challenges arise, but adaptability can mitigate their impact. Implementing these strategies fosters a more efficient PCB production environment.

Related Posts

-

2025 Guide: How to Master PCB Design for Innovative Electronics Projects

-

2026 Best PCB Prototyping Techniques for Efficient Product Development

-

Why Understanding PCB Production is Essential for Modern Electronics

-

Top PCB Prototyping Techniques for Efficient and Cost Effective Design?

-

Why Printed Circuit Boards Are Essential for Modern Electronics Development

-

What is PCB Fabrication The Complete Guide to Understanding PCB Manufacturing