How to Choose the Right PCB Types for Your Project?

Choosing the right PCB types for your project is a crucial step in the design process. According to a report by industry leader IPC, nearly 30% of project delays are tied to improper PCB selection. Understanding various pcb types can significantly enhance project efficiency and minimize costs.

John Doe, a renowned expert in PCB technology, states, "Selecting the appropriate PCB type can make or break your project." His insight underscores the importance of careful consideration. Different pcb types have unique properties that impact electrical performance, thermal management, and production costs. For instance, rigid PCBs are common in consumer electronics, while flexible PCBs are increasingly used in space-constrained applications.

The proliferation of technology demands a careful approach to PCB selection. With rapid advancements, staying updated on new pcb types becomes essential. Many designers may overlook the specific needs of their projects. It’s easy to assume one type fits all, but that's rarely the case. Reflecting on past mistakes can lead to better outcomes. Taking the time to analyze and choose wisely will yield better results in the long run.

Understanding the Basics of PCB Types and Their Applications

When selecting a printed circuit board (PCB) for your project, understanding different types is crucial. There are several common PCB types, including single-sided, double-sided, and multi-layer boards. Each serves unique applications. Single-sided boards are often simpler and less expensive. They work well for basic circuits but have limitations in complexity. Double-sided boards allow for more electronics in a compact space.

In contrast, multi-layer PCBs combine several layers. They support dense circuit designs, but manufacturing can be complex and costly. Consider the specific needs of your project. If your device demands high-frequency performance, rigid flex PCBs might be advisable. These boards provide flexibility without sacrificing performance.

Choosing the right PCB type requires thought. You may find some designs need adjustments. Consider factoring in your budget and timeline. A more complex board could delay your project. It's a balance between functionality and feasibility. Making decisions involves trade-offs. Don't rush; assess your requirements carefully.

PCB Types and Their Applications

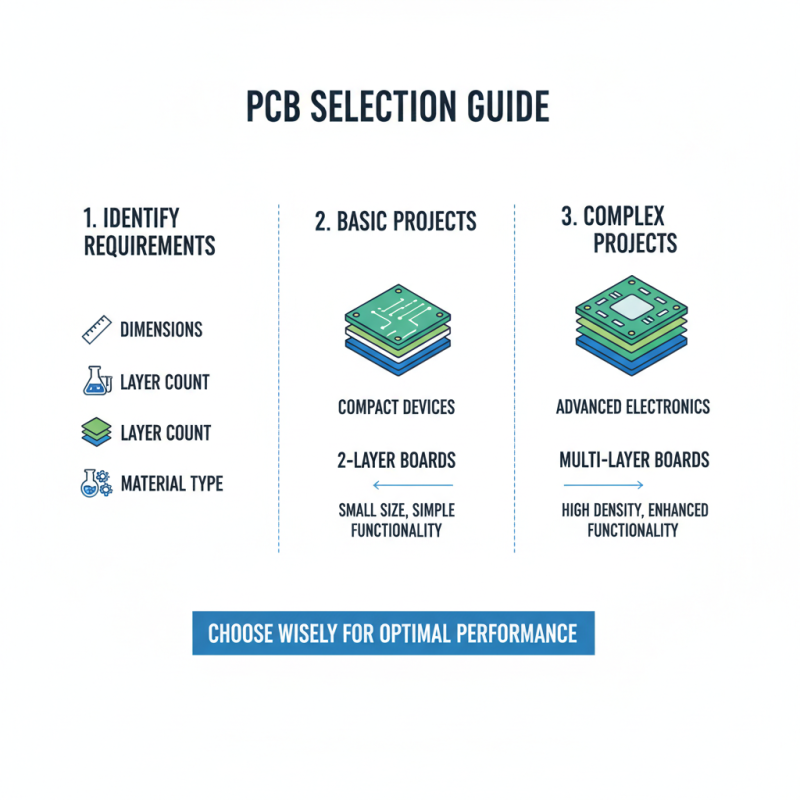

Identifying Your Project Requirements for PCB Selection

When selecting the right PCB for your project, understanding requirements is crucial. Start by identifying the key specifications. This includes dimensions, layer count, and material types. For example, a compact device might need a small-sized board with two layers. In contrast, complex electronics require multi-layer boards for better functionality.

You should also consider the operating environment. Will the PCB be exposed to high temperatures or moisture? If so, choose materials that resist these conditions. Sometimes, the standard options may not fit your needs, leading to frustration. Testing and revisions might be needed to refine your choice.

Power requirements are another major factor. Assess the voltage and current specifications accurately. If unknown, this can lead to inefficiencies. Think about the overall layout as well. A poor layout can cause signal issues. These details matter, even if they're often overlooked. Reflect on these points to ensure an effective decision for your project.

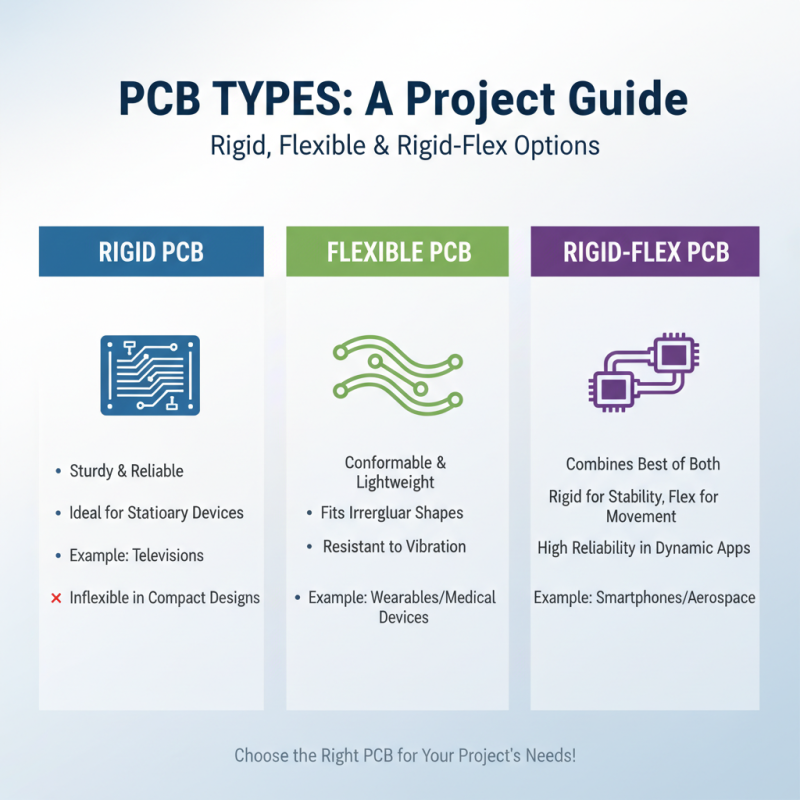

Comparing Rigid, Flexible, and Rigid-Flex PCBs

When selecting PCB types for your project, understanding rigid, flexible, and rigid-flex options is crucial. Rigid PCBs are sturdy and reliable. They are ideal for devices that won’t undergo much movement. For instance, think of traditional electronic devices like televisions. However, their inflexibility can be a downside in compact designs.

Flexible PCBs, on the other hand, offer versatility. They bend easily and fit into complicated shapes. This makes them great for wearables or compact gadgets. A common challenge with flexible designs is ensuring durability in high-stress areas. Thin materials could lead to connections failing over time.

Rigid-flex PCBs combine the best features of both worlds. This hybrid type is used when space is tight but flexibility is needed. For example, managing complex designs in a smartphone. **Tips:** When choosing a PCB, consider strength and weight first. Think about the environment where your PCB will be used. Are there heat or mechanical stress factors to consider? Always prototype before making a large order to catch potential design flaws early.

Evaluating Material Quality and Performance for PCB Durability

Choosing the right PCB material is essential for your project's success. Material quality directly affects durability and performance. Different applications demand different characteristics. For instance, high-frequency circuits benefit from low-loss materials. In contrast, environment-sensitive projects may require moisture-resistant options. Knowing the specific requirements of your application is key.

**Tip:** Assess the thermal management properties of your chosen material. Poor thermal performance can lead to failures. Consider the operating temperature range and conductivity.

You might think all materials are similar, but that's misleading. There are nuances like laminate thickness and copper weight. These factors impact strength and flexibility. A rigid board may not fit well in certain designs. This oversight can lead to costly redesigns.

**Tip:** Always test small batches before mass production. This step can save you from making large investments in inferior materials.

Lastly, don't ignore the environmental impact. Some materials are harder to recycle or dispose of. This can influence your project's overall sustainability. Think critically about the long-term implications of your material choices.

How to Choose the Right PCB Types for Your Project? - Evaluating Material Quality and Performance for PCB Durability

| PCB Type | Material | Key Characteristics | Durability Rating | Typical Applications |

|---|---|---|---|---|

| FR-4 | Fiberglass Epoxy | Good electrical insulation, low cost | Moderate | Consumer electronics, automotive |

| Polyimide | Polyimide Film | High thermal stability, flexible | High | Aerospace, medical devices |

| Metal Core | Aluminum or Copper | Excellent heat dissipation | High | LED applications, power supplies |

| Ceramic | Ceramic Material | High thermal conductivity, high dielectric strength | Very High | RF applications, high frequency |

| CEM-1 | Composite Epoxy Material | Moderate cost, good overall performance | Moderate | Consumer products, industrial equipment |

Cost Considerations and Budgeting for PCB Types in Your Project

When planning a PCB project, budgeting is crucial. Many factors affect the cost of PCBs. The material, complexity, and size all play significant roles. According to industry reports, roughly 60% of PCB costs stem from raw materials and production techniques. High-quality materials can lead to better performance, but they are often more expensive.

Design complexity can also inflate costs. Basic designs may start at $2 per square inch, while complex multilayer boards can exceed $10. It's essential to evaluate the project requirements closely. Are advanced features necessary? Sometimes, a simpler design may suffice, saving funds for future upgrades.

On top of component choices, consider the production scale. Low-volume runs are typically pricier per unit. A batch of 100 boards could cost significantly more than 1,000. Finding the sweet spot between quantity and quality is key. But if only a few prototypes are needed, investing in a lower-cost option could be wiser. Balancing quality with budget demands ongoing reflection and adjustment.

Related Posts

-

What is PCB Production and How Does it Impact Electronics Industry?

-

Why Printed Circuit Boards Are Essential for Modern Electronics Development

-

2025 Guide: How to Master PCB Design for Innovative Electronics Projects

-

Top Tips for Choosing the Right PC Boards for Your Needs?

-

How to Design Printed Circuit Boards for Beginners and Experts

-

2026 Best PCB Prototyping Techniques for Efficient Product Development