2026 How to Choose the Best Aluminum PCB for Your Project?

Choosing the right aluminum PCB can be challenging. With various options available, knowing what to look for is crucial. Aluminum PCBs are known for their excellent thermal conductivity and durability. They are often used in LED lighting applications, power supplies, and other electronic devices requiring efficient heat dissipation.

When selecting an aluminum PCB, consider factors like thickness, finish, and configuration. Each choice impacts performance and cost. An ideal thickness ensures durability while maintaining lightweight properties. A suitable finish can enhance soldering, impacting reliability. Additionally, the specific design configuration must meet your project's requirements.

However, navigating these choices can feel overwhelming. Many designers may overlook important specifications or underestimate their impact. Reflecting on past projects helps inform better decisions. Evaluating previous designs can lead to more effective solutions this time. Remember, choosing the best aluminum PCB is essential for the success of your project.

Understanding Aluminum PCBs and Their Applications

Aluminum PCBs have become essential in many applications due to their excellent thermal management. A recent industry report highlights that the global aluminum PCB market is projected to grow at a compound annual growth rate of 7.5% by 2025. This growth stems from the increasing demand in sectors like LED lighting, automotive, and telecommunications.

These circuit boards efficiently dissipate heat, which is crucial for performance. For instance, LED lighting systems can exceed 250 degrees Fahrenheit, making effective heat dissipation imperative. However, not all aluminum PCBs are created equal. The choice of thickness, substrate materials, and surface treatment is vital. Some manufacturers might skimp on material quality, leading to reliability issues.

In examining designs, manufacturers face challenges. While some prefer thicker aluminum layers for durability, others might prioritize weight. Balancing these factors is key. Additionally, the cost of production can vary widely. It's crucial to evaluate the long-term benefits against the initial expense. This evaluation often requires a deeper understanding of specific project needs and application environments.

Key Factors to Consider When Choosing Aluminum PCBs

When selecting aluminum PCBs for your project, consider heat dissipation, cost efficiency, and environmental factors. A study by the IPC shows that effective thermal management is crucial for performance. Overheating can lead to component failure. Aluminum PCBs can dissipate heat better than standard FR-4 boards. This quality is essential in high-power applications.

Tips: Evaluate your project's heat density. Higher heat density requires better thermal performance.

Cost is another significant factor. While aluminum PCBs can be more expensive upfront, they save costs in long-term reliability and performance. Research suggests that the lifespan of a product using aluminum PCBs may be extended by up to 30%. This longevity makes them a smarter choice in many cases.

Tips: Compare quotes from multiple suppliers. Quality may vary significantly.

Lastly, consider environmental conditions. Aluminum PCBs perform well in extreme temperatures and humid environments. However, improper choices can lead to reduced efficiency or failures. Analyze your project's demands carefully. Selecting the wrong type can lead to setbacks or increased costs.

2026 How to Choose the Best Aluminum PCB for Your Project? - Key Factors to Consider When Choosing Aluminum PCBs

| Factor | Description | Importance Level | Recommended Value |

|---|---|---|---|

| Thermal Conductivity | The ability of the PCB to dissipate heat. | High | > 2 W/mK |

| Layer Count | Number of layers in the PCB design. | Medium | 1-4 Layers |

| Board Thickness | Thickness of the aluminum core. | High | 1.6 mm |

| Surface Finish | Type of surface treatment for solderability. | Medium | HASL or ENIG |

| Cost | Overall production cost of the PCB. | High | Budget-specific |

| Flexibility Requirements | Need for bending or flexing in the design. | Low | Rigid is standard |

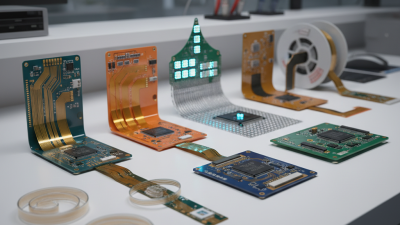

Comparing Different Types of Aluminum PCBs

When comparing different types of aluminum PCBs, several crucial factors come into play. Aluminum PCBs are essential for LED applications, with a thermal conductivity value often reaching up to 2.0 W/mK. This property helps in heat dissipation, which is vital for the longevity of electronic components. But not all aluminum boards deliver the same thermal performance. A study found that poor thermal management can reduce component life by over 40%.

Another factor to consider is the thickness of the aluminum base. Thicker bases provide better stability but come at a higher cost. For instance, boards with a thickness of 2mm show a notable increase in performance for high-current applications. Additionally, the surface finish of the PCB significantly impacts solderability and reliability. It's common for manufacturers to overlook this, leading to potential failures in assembly.

Different aluminum alloys also have implications on performance. For example, 1050 and 6061 alloys are frequently used, each offering unique benefits. The choice between them can affect machining and thermal characteristics. Many projects could benefit from a careful selection based on specific needs, yet decisions are often based simply on availability. This oversight can influence the overall success of the project.

Comparison of Different Types of Aluminum PCBs

This chart presents a comparison of various types of aluminum PCBs based on their thermal conductivity, dielectric strength, and weight. Each type is evaluated for its suitability in different project requirements.

Evaluating Heat Dissipation and Thermal Management Features

When selecting the best aluminum PCB for your project, thermal management is crucial. Heat dissipation directly affects the performance and longevity of your electronic components. A well-designed PCB helps spread heat evenly. This prevents hotspots that could damage sensitive parts.

Look for multilayer designs. They often feature buried vias and thermal vias, which enhance heat dissipation. The surface area matters too. A larger area allows for better air circulation. Additionally, consider the thermal conductivity of the aluminum substrate. Higher conductivity ensures faster heat transfer.

However, achieving optimal thermal management can be challenging. Not every design meets the necessary criteria for all applications. You may find that some PCBs do not provide adequate heat sinking. This could lead to unexpected failures over time. Assessing your project's unique requirements is essential. Balancing cost and performance is often tricky. Aim for efficiency, but don't overlook potential compromises.

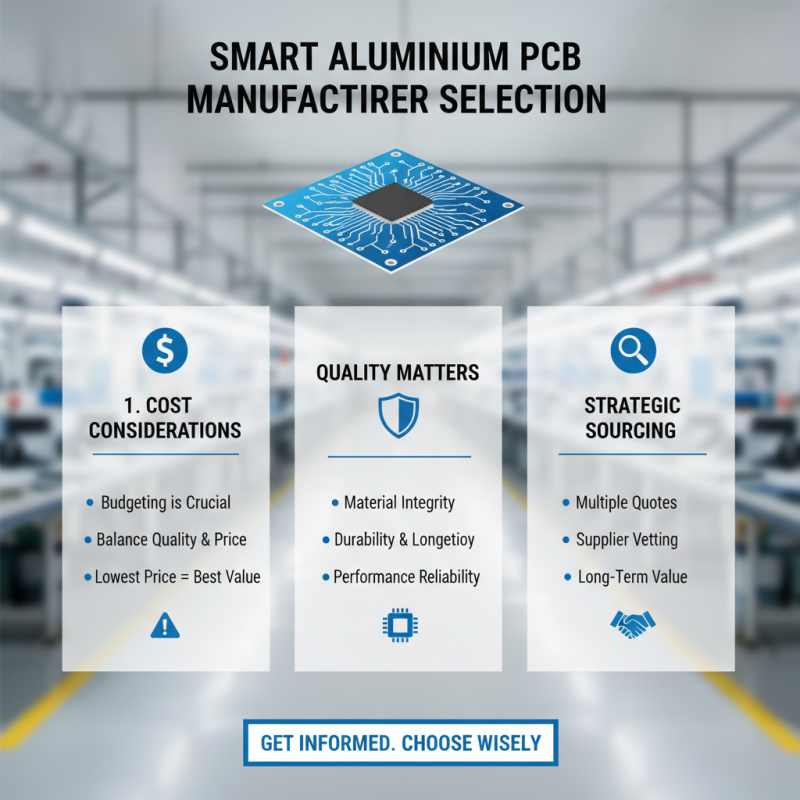

Assessing Cost and Manufacturer Selection for Aluminum PCBs

When selecting manufacturers for aluminum PCBs, cost is a key factor. It's essential to balance quality and price. Some manufacturers may offer low rates but might compromise on material quality. This decision can impact the longevity and performance of the PCB. Getting quotes from multiple suppliers is necessary. However, the lowest price isn't always the best option.

Assessing manufacturer capabilities is equally crucial. Review their production processes and certifications. A reputable manufacturer should provide information about their equipment and technology. This transparency helps ensure they meet your project requirements. Don't hesitate to ask for sample products. It’s a practical way to evaluate their quality before committing.

Lastly, consider the location of the manufacturer. Shipping costs and time can affect your project. Domestic suppliers may seem costly at first but can provide faster turnaround times. In contrast, overseas options could reduce initial costs but may introduce delays. Reflecting on these points can help you find the right balance for your aluminum PCB project.

Related Posts

-

What is PCB Production and How Does it Impact Electronics Industry?

-

Top Circuit Boards Technologies Transforming Electronics Today?

-

Why Understanding PCB Production is Essential for Modern Electronics

-

10 Best PCB Flex Technologies to Enhance Your Electronic Designs

-

What is PCB Fabrication and How Does it Impact Your Electronics Projects

-

Top 10 Circuit Board Design Techniques for Beginners to Master?