Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects

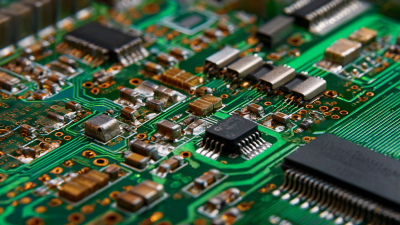

In the ever-evolving field of electronics, the choice of components plays a pivotal role in the success of any project. One of the most essential elements in the development of reliable and efficient electronic devices is the printed PCB board. These boards not only serve as a foundation for electrical connections but also enhance the overall functionality of the project. By integrating advanced technologies and manufacturing processes, printed PCB boards have emerged as a preferred option for engineers and hobbyists alike.

The benefits of using printed PCB boards extend beyond mere convenience. They offer improved performance, durability, and compactness compared to other types of circuit boards. In addition, their design flexibility allows for innovative layouts that can accommodate complex circuitry. As we explore the top five advantages of printed PCB boards, it becomes evident that they are indispensable tools for anyone looking to create cutting-edge electronic devices. Whether you're a seasoned engineer or a novice enthusiast, understanding the remarkable benefits of printed PCB boards can significantly elevate the quality and efficiency of your electronics projects.

Advantages of Printed PCB Boards for Electronics Development

Printed PCB boards offer numerous advantages that significantly enhance electronics development. One of the foremost benefits is their ability to provide a compact and organized platform for electronic components. This efficient layout minimizes the space required for assembling circuits, allowing for more complex designs in smaller devices. Additionally, PCBs facilitate easier troubleshooting and repair, as the printed connections create a clear path to follow when diagnosing issues.

Another key advantage of using printed PCB boards is their reliability and durability. Unlike breadboards and prototyping boards, PCBs are built to withstand environmental stressors such as temperature variations and humidity, ensuring consistent performance over time. The precision manufacturing process also contributes to better signal integrity, reducing noise and interference in sensitive electronic applications. Furthermore, PCBs are compatible with automated production, which streamlines the manufacturing process and ensures higher accuracy, ultimately leading to cost savings during large-scale production.

Cost-Effectiveness of Printed Circuit Boards in Projects

Printed circuit boards (PCBs) have become a cornerstone in the design and manufacturing of electronics, especially for hobbyists and professionals alike. One of the primary advantages of using printed PCBs is their cost-effectiveness. Compared to traditional wiring methods, PCBs significantly reduce materials and labor costs. The mass production of PCBs further drives down costs, as manufacturers can optimize material use and streamline processes. This efficiency allows electronics projects, even at a small scale, to remain budget-friendly while maintaining quality and reliability.

When working on PCB projects, consider these tips to maximize cost-effectiveness. First, pool components from reputable suppliers that offer bulk discounts; this strategy ensures you save significantly on individual parts. Second, leverage design software that optimizes PCB layouts to minimize material waste and enhance functionality without unnecessarily increasing the cost. Lastly, opt for a local PCB manufacturer or one that offers competitive pricing and quick turnaround times to further enhance savings on shipping and handling.

By focusing on these cost-effective strategies, not only can you reduce expenses related to your electronics projects, but you can also enhance your overall project efficiency. This ultimately enables both beginners and experienced developers to explore innovative designs without breaking the bank.

Enhanced Durability and Longevity of PCB Solutions

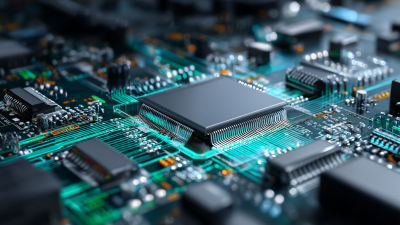

When it comes to electronics projects, the durability and longevity of printed PCB boards are crucial factors that contribute to their overall performance. Printed circuit boards (PCBs) are designed to withstand various environmental conditions, including temperature fluctuations and moisture. This resilience ensures that the electronic devices powered by these PCBs can function reliably over extended periods. The use of high-quality materials in PCB manufacturing enhances their resistance to wear and tear, ensuring that your projects stand the test of time.

**Tips:** When selecting PCB materials, consider using FR-4, a common laminate that offers excellent thermal stability and mechanical strength. Additionally, look for PCBs with a conformal coating to protect against moisture and dust, which can significantly increase their lifespan.

Furthermore, integrating thicker copper layers can also enhance the durability of your PCBs. This not only improves current carrying capacity but also helps in better heat dissipation, ultimately leading to longer-lasting electronic components. Ensuring proper soldering techniques and utilizing quality components during assembly will further contribute to the longevity of your PCB solutions.

**Tips:** Always adhere to recommended soldering temperatures and avoid excessive heat to preserve the integrity of the PCB. Regular maintenance and inspection of your projects can catch potential issues early, extending their effective lifespan.

Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects

Improved Electromagnetic Compatibility with PCB Use

Using printed PCB boards significantly enhances electromagnetic compatibility (EMC) in electronics projects. By providing a structured layout, PCBs minimize electromagnetic interference (EMI), which can disrupt the normal operation of electronic components. The design of a PCB allows for the careful placement of traces and components, creating predictable paths for signals and reducing the potential for crosstalk. This careful organization is essential, especially in complex circuits where multiple signals must coexist without degrading performance.

Additionally, the materials used in printed PCBs contribute to improved EMC. High-quality substrates can effectively shield sensitive components from external electromagnetic disturbances. Implementing ground planes within the PCB design not only helps to absorb noise but also aids in maintaining a steady reference point for signal integrity. Overall, the synergy of thoughtful design and quality materials makes printed PCBs a superior choice for achieving robust electromagnetic compatibility in electronic projects.

Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects - Improved Electromagnetic Compatibility with PCB Use

| Benefit | Description | Impact Level | Use Case |

|---|---|---|---|

| Improved Electromagnetic Compatibility | PCBs are designed to minimize electromagnetic interference, enhancing device performance. | High | Consumer electronics, RF devices |

| Compact Design | Allows for smaller and more efficient electronic designs. | Medium | Wearable devices, mobile gadgets |

| Cost Efficiency | Reduces assembly time and manufacturing costs. | High | High-volume production |

| Enhanced Reliability | Increases lifespan of components and reduces failure rates. | High | Critical applications, automotive electronics |

| Design Flexibility | Facilitates complex layouts and multiple layers for intricate designs. | Medium | Advanced computing, industrial equipment |

| Thermal Management | Improves heat dissipation, preventing overheating. | High | Power electronics, LED lighting |

| Scalability | Easily scalable for large production runs. | High | Consumer products, IoT devices |

| Automation Compatibility | Supports automated assembly, enhancing production speed. | Medium | Manufacturing lines, assembly robotics |

| Customization Options | Allows for tailored designs to meet specific project needs. | Medium | Prototyping, niche markets |

| Environmentally Friendly | Select materials and processes can reduce environmental impact. | Low | Eco-friendly products, green technology |

Streamlined Production and Prototyping Processes Using PCBs

The integration of printed circuit boards (PCBs) into electronics projects significantly streamlines both production and prototyping processes. Recent advancements in technologies such as bio-microsystem integration and lab-on-PCB systems have further enhanced the capabilities of PCBs, allowing engineers to create effective micro-total analysis systems (µTAS). This evolution in PCB technology promotes rapid prototyping, minimizing the redesign cycles that often hinder project timelines. Companies are now able to bring their innovative concepts to life more swiftly, demonstrating the importance of leveraging PCBs in modern electronic design.

Moreover, the emergence of services focused on rapid prototype PCB assembly reflects the industry's commitment to accelerating innovation. By optimizing production workflows, these services enable faster testing and refinement of designs, reducing the time from concept to market. Enhanced tools and collaborative platforms are also simplifying PCB design integration, allowing engineers to streamline processes, such as PCB-to-wire harness designs, ultimately facilitating more efficient project development. This ongoing evolution in PCB technology not only supports the engineering community but also assures that high-quality prototypes can be realized quickly and effectively.

Related Posts

-

How Printed Circuit Boards Shape the Future of Technology with Insights from Industry Trends

-

Exploring the Advantages of Aluminum PCBs in Modern Electronic Design: A Complete Guide

-

Mastering Circuit Board Design Fundamentals for Beginners in Electrical Engineering

-

The Future of Electronics: How Flexible Printed Circuit Boards are Revolutionizing Device Design

-

Understanding the Essential Role of Printed PCBs in Modern Electronics