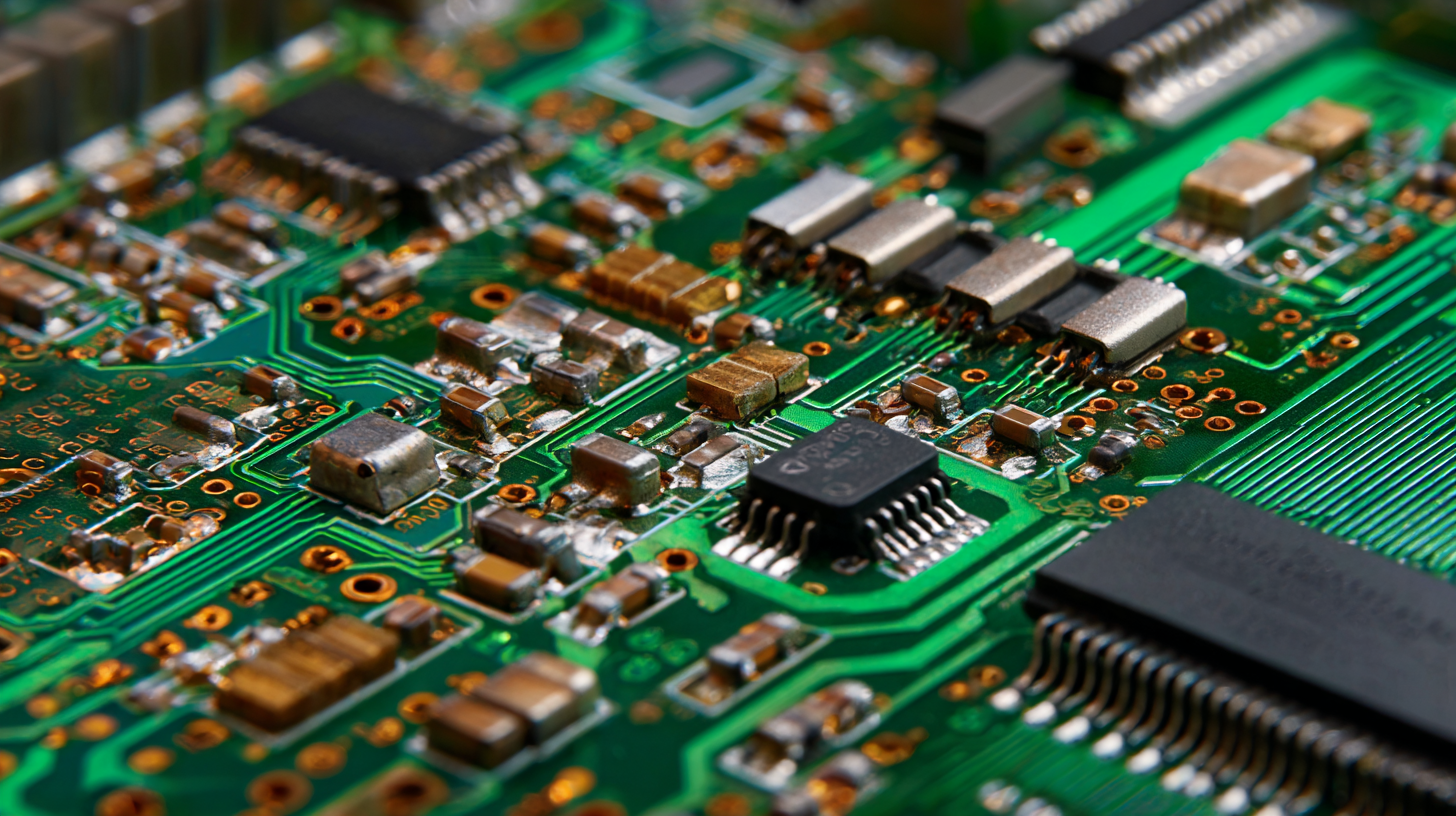

Exploring the Advantages of Aluminum PCBs in Modern Electronic Design: A Complete Guide

In the rapidly evolving field of electronics, the material composition of printed circuit boards (PCBs) plays a critical role in the performance and reliability of devices. Among the various types of PCBs, aluminum PCBs have garnered significant attention due to their superior thermal management and mechanical stability. According to a recent report by MarketsandMarkets, the global aluminum PCB market is projected to reach $5.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.2% from 2020. This growth is largely driven by the increasing demand for high-performance lighting systems and telecommunications equipment, which benefit from the lightweight and heat dissipation characteristics of aluminum PCB technology. As modern electronic designs strive for efficiency and longevity, understanding the advantages and applications of aluminum PCBs becomes essential for manufacturers and engineers aiming to optimize their products for an increasingly competitive market.

Advantages of Aluminum PCBs: A Shift in Thermal Management Efficiency in Electronics

Aluminum PCBs are revolutionizing thermal management in modern electronic design. Traditional FR4 PCBs often struggle to dissipate heat effectively, leading to potential performance issues and reduced lifespan of components. According to a report by IPC, overheating can decrease the reliability of electronic assemblies by up to 30%. In contrast, aluminum PCBs can manage heat more efficiently due to their excellent thermal conductivity, which can be as high as 200 W/mK. This efficiency not only prolongs the lifespan of components but also enhances overall circuit performance.

**Tip:** When designing with aluminum PCBs, it’s crucial to optimize layout to maximize heat dissipation. Ensure that high-heat components are placed strategically to leverage the PCB’s thermal properties.

Moreover, the shift towards aluminum PCBs aligns well with the trends towards miniaturization and increased functionality in electronics. The lightweight nature of aluminum coupled with its robust thermal management capabilities makes it an ideal choice for compact devices like LED lighting and high-power electronics. Research indicates that implementing aluminum PCBs can improve thermal performance by as much as 40%, significantly enhancing device reliability in demanding environments.

**Tip:** Consider employing thermal interface materials (TIMs) when mounting components onto aluminum PCBs to further improve heat transfer efficiency.

Cost-Effectiveness of Aluminum PCBs in High-Volume Production: An Economic Analysis

Aluminum PCBs have gained significant traction in modern electronic design due to their cost-effectiveness, especially in high-volume production scenarios. One of the primary economic advantages lies in their efficiency in thermal management, which allows for reduced material costs and enhanced product lifespans. Unlike traditional FR-4 boards, aluminum PCBs efficiently dissipate heat generated by components, minimizing the need for additional cooling solutions. This not only translates to lower manufacturing expenses but also facilitates the production of smaller, lightweight devices, a crucial factor in today’s competitive market.

Furthermore, the manufacturing process of aluminum PCBs can streamline production times, resulting in greater output without compromising quality. With advancements in production techniques, these boards can be fabricated quickly and at scale, leading to lowered labor costs and improved profit margins for manufacturers. As the demand for compact and high-performance electronic devices continues to rise, the economic analysis highlights that investing in aluminum PCBs is a strategic move that aligns with both cost reduction and productivity enhancement, ultimately benefiting companies in the long run.

Lightweight Design Benefits: How Aluminum PCBs Enhance Portability in Electronic Devices

Aluminum PCBs have gained significant traction in modern electronic design, particularly due to their lightweight characteristics that greatly enhance the portability of devices. Traditional circuit boards, often made from heavier materials, can add unnecessary bulk to products like smartphones and portable computing devices. In contrast, aluminum PCBs are known to reduce weight by up to 40%, enabling manufacturers to create sleeker designs without compromising on functionality. According to a recent report by TechNavio, the demand for lightweight electronic components is projected to grow by over 15% annually, underscoring the importance of materials like aluminum in meeting consumer preferences for portability.

Additionally, the thermal management capabilities of aluminum PCBs contribute to their advantages in compact designs. They provide superior heat dissipation compared to conventional FR4 boards, allowing for smaller and more powerful components to be integrated without overheating. This is particularly crucial in applications such as LED lighting and high-performance computing, where maintaining optimal operating temperatures is essential. Industry insights from IPC indicate that nearly 30% of electronic failures can be attributed to inadequate thermal management, highlighting the value aluminum PCBs bring in ensuring both portability and reliability in electronic devices.

Durability and Longevity of Aluminum PCBs: Impact on Product Lifecycle and Reliability

Aluminum printed circuit boards (PCBs) have gained recognition in modern electronic design due to their exceptional durability and longevity. Unlike traditional PCBs that incorporate multiple layers of glass fiber and hard plastics, aluminum PCBs provide greater thermal management and structural integrity. This makes them particularly valuable in applications where heat dissipation is critical, such as in aerospace and communication technologies. By reducing the risk of warping or damage under high-stress conditions, aluminum PCBs can significantly enhance the reliability of electronic products throughout their lifecycle.

The impact of aluminum PCBs on product durability is profound. Their robust construction allows for extended operational periods without degradation, which is essential for maintaining reliability in critical devices. As the demand for environmentally sustainable solutions grows, the ability of aluminum PCBs to withstand harsh conditions and reduce the frequency of replacements aligns with industry trends towards longevity and efficiency. This not only contributes to a reduction in waste but also supports the ongoing shift towards sustainable electronic design, ensuring that products remain functional and reliable over an extended period.

Innovative Applications of Aluminum PCBs in LED Technology and High-Power Devices

Aluminum PCBs are increasingly becoming essential in modern electronic design, especially in the realms of LED technology and high-power devices. Their superior thermal conductivity allows for efficient heat dissipation, which is crucial for maintaining performance and longevity in high-power applications. With the rapid growth of the electric vehicle sector, for instance, the demand for robust heat management solutions in controller circuits underlines the significance of aluminum PCBs in ensuring reliability.

Moreover, as semiconductor technologies advance, such as the emerging silicon carbide (SiC) innovations, the role of aluminum PCBs becomes even more prominent. These boards enable higher power handling and improved performance, which is vital in the context of high-frequency operations associated with 5G and IoT applications. The projected market growth for insulated metal substrates further highlights the trend towards integrating aluminum PCBs into new product designs, thereby facilitating the ongoing technological evolution across various sectors, including transportation, consumer electronics, and beyond.