2026 Best Circuit Boards What to Look For and Top Options?

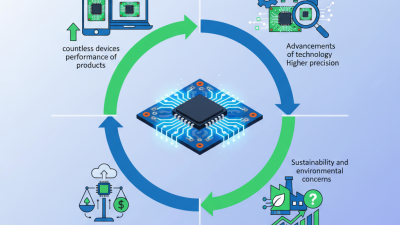

In the rapidly evolving world of electronics, circuit boards play a pivotal role. As industry expert Dr. Emily Carter states, “Circuit boards are the backbone of modern technology.” Selecting the right circuit board is crucial for performance and reliability. With countless options available, understanding the key factors is essential.

When exploring the best circuit boards for 2026, one must consider several aspects. Material quality, design complexity, and manufacturing processes all significantly impact the final product. For instance, is the circuit board designed for flexibility or rigidity? Are the components suitable for high frequencies? These details can make or break the efficiency of an electronic device.

While many boards may look similar, their applications vary greatly. Not every circuit board is ideal for every project. Some choices can lead to failures if not scrutinized carefully. Reflecting on designs and functionalities helps ensure an optimal selection. The dynamic nature of the circuit board industry demands continuous learning and adaptation. Recognizing the specifics can guide users toward the best options.

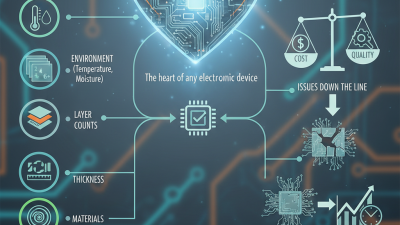

Key Features to Consider When Choosing Circuit Boards for 2026

When choosing circuit boards for 2026, several key features make a significant difference. Material quality is one aspect that impacts durability. High-grade materials ensure longevity. Look for boards that can withstand temperature changes and humidity. This will help prevent failure in various environments.

Next, consider layer count. More layers can enhance functionality. However, they also increase manufacturing costs. It’s essential to find a balance that meets your specific needs without overspending. The board's thickness is also crucial. Thicker boards typically offer better stability, but they can be heavier and more challenging to work with.

Finally, take into account the complexity of the design. Simpler designs might be easier to manage. Yet, they may limit performance. As technology evolves, striking a balance between complexity and practicality becomes vital. Think carefully about these elements to ensure you make the right choice for your projects.

Top Circuit Board Manufacturers to Watch in 2026

As we look towards 2026, it's critical to focus on emerging circuit board manufacturers. The industry is evolving rapidly, driven by advancements in technology. Many companies are adopting innovative materials and processes to enhance performance. This shift emphasizes the need for reliability and efficiency in circuit board design.

One trend to watch is the increasing emphasis on sustainability. Some manufacturers are experimenting with eco-friendly materials. This not only reduces waste but also appeals to environmentally conscious consumers. However, there is still a long way to go before sustainable practices are the norm.

Quality control remains a concern in circuit board production. Some manufacturers struggle with consistency in their output. Imperfections can lead to significant issues in performance and reliability. Identifying manufacturers that prioritize meticulous testing and quality assurance can be challenging. It is vital to seek out those who show a commitment to excellence.

2026 Best Circuit Boards: Key Metrics Overview

Innovative Technologies in Circuit Board Design for 2026

As we look toward 2026, circuit board design is set for innovative breakthroughs. Designers are leveraging advanced materials that enhance performance. New substrates like flexible or high-frequency materials are gaining popularity. They help in reducing weight and improving signal integrity.

When choosing a circuit board, consider the manufacturing process. Techniques like additive manufacturing are shaping the future. They provide precision and efficiency. However, they can be costly. Balance is key.

Tips: Pay attention to the thermal management solutions. Effective heat dissipation can prolong the lifespan of a circuit board. Always ask about testing methods too. Ensuring reliability starts with robust testing protocols. Be critical about the choices you make. Reflect on their long-term impacts.

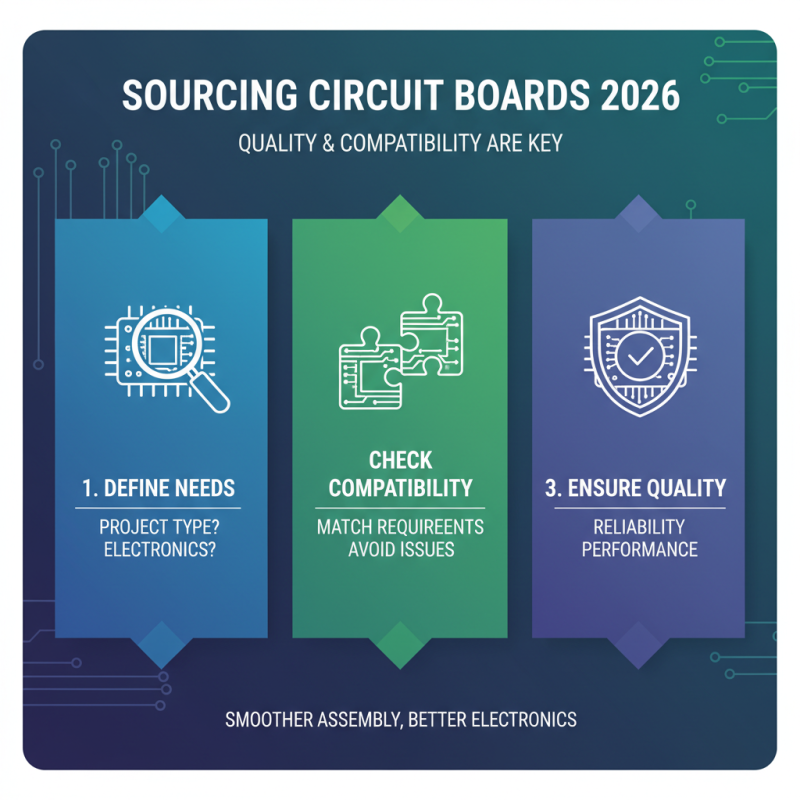

Best Practices for Sourcing and Purchasing Circuit Boards in 2026

When sourcing circuit boards in 2026, it's crucial to focus on quality and compatibility. Start by identifying your specific project needs. What type of electronics will you be integrating? Ensure your circuit boards match these requirements. Compatibility reduces headaches during assembly.

Keep an eye on suppliers with a proven track record. Investigate their manufacturing practices. Poor quality can lead to malfunctions. Request samples to assess performance. Look for boards that have undergone strict testing. This step is often overlooked but vital for reducing future costs.

Consider sustainability in your sourcing decisions. Ethical production is becoming increasingly important. Seek manufacturers that prioritize eco-friendly materials. This can provide a competitive edge. However, not every supplier may meet these standards. Continuously evaluate your choices and be open to change.

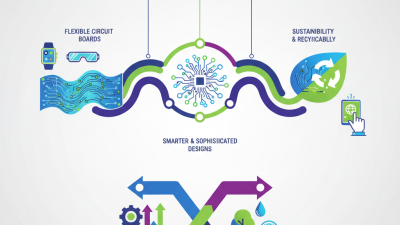

Emerging Trends in Circuit Board Applications for Various Industries in 2026

The year 2026 is set to revolutionize circuit board applications across various industries. Emerging technologies are reshaping how we use these essential components. For instance, automation and IoT integration will significantly enhance efficiency. Smart devices are becoming more prevalent, requiring advanced circuit boards to function seamlessly.

Tips: Consider energy efficiency when selecting circuit boards. This can lead to long-term savings and reduced environmental impact.

In the healthcare sector, there is a growing demand for biocompatible circuit boards. These are essential for wearables and medical devices. However, developers must ensure reliability and safety. Innovators need to stay ahead of regulatory changes while maintaining quality standards.

Tips: Always test prototypes thoroughly. This helps avoid costly adjustments later. Focus on user feedback to identify areas for improvement.

Industries are also focusing on sustainable materials for circuit boards. Using eco-friendly options is becoming a priority. Yet, balancing performance and sustainability remains a challenge. The market is evolving rapidly, and companies must adapt swiftly to stay competitive.

2026 Best Circuit Boards - Key Dimensions and Features

| Dimension | Description | Emerging Applications | Material Type | Expected Lifespan |

|---|---|---|---|---|

| Thickness | Standard thickness varies from 0.2mm to 3.2mm | Consumer Electronics, IoT Devices | FR-4, Polyimide | 5-10 years |

| Layer Count | Single to 16 layers | Medical Devices, Aerospace | Alumina, Teflon | 10-20 years |

| Impedance | Generates minimal signal loss | Telecommunication, Automotive | High-speed Laminates | 15-25 years |

| Surface Finish | Lead-Free Solder, Immersion Gold | Green Energy Solutions, Robotics | HASL, OSP | 8-15 years |

| Thermal Management | Materials designed for heat dissipation | High-Power Applications, Electric Vehicles | Thermal Interface Materials | 10+ years |

Related Posts

-

Top 10 PC Boards for Optimal Performance in 2023

-

Top Tips for Choosing the Right PC Boards for Your Needs?

-

Why Printed Circuit Boards Are Essential for Modern Electronics Development

-

Top Circuit Boards Technologies Transforming Electronics Today?

-

What is PCB Production and How Does it Impact Electronics Industry?

-

2025 Guide: How to Master PCB Design for Innovative Electronics Projects